Hot Strip Steel Mill Doubles Lighting Output While Reducing The Fixtures Installed by 25%

The Customer’s Lighting Challenges:

Our customer was facing lighting challenges in their high-temperature environment. The steel mill was continuously replacing burned-out lights every 12 months. When our heavy industrial lighting specialists surveyed the facility and completed a lighting audit, they recorded an average ambient temperature rating of 130 degrees Fahrenheit (or 54 degrees Celsius). LED lighting does not usually perform well in such high temperatures.

After the lighting audit, our team understood the challenges present at the steel mill, including high temperatures, and created an LED lighting solution for their specific plant. Here are our findings:

Audit Findings:

- High Temperatures (130°F) Causing Lights to Fail

- Replacing 260 Lights Every 12 Months (Fixtures Did Not Have a Replaceable Driver)

- Labour & Time Spent Replacing 60 lb Fixtures for Every Light Failure

- Only Achieving 15 Foot-Candles at a 45-Foot Mounting Height

- Had a Planned Maintenance Shut Down Scheduled & Needed a New Lighting Solution Quickly

LED Lighting Solution:

Our high-temperature LED replacement fixture will last a minimum of 5 times longer than their current lighting. We replaced their current lighting with our 240W low-volt LED fixture with 36,000 lumens. Here is the breakdown of how our lighting solution benefitted our steel mill customer:

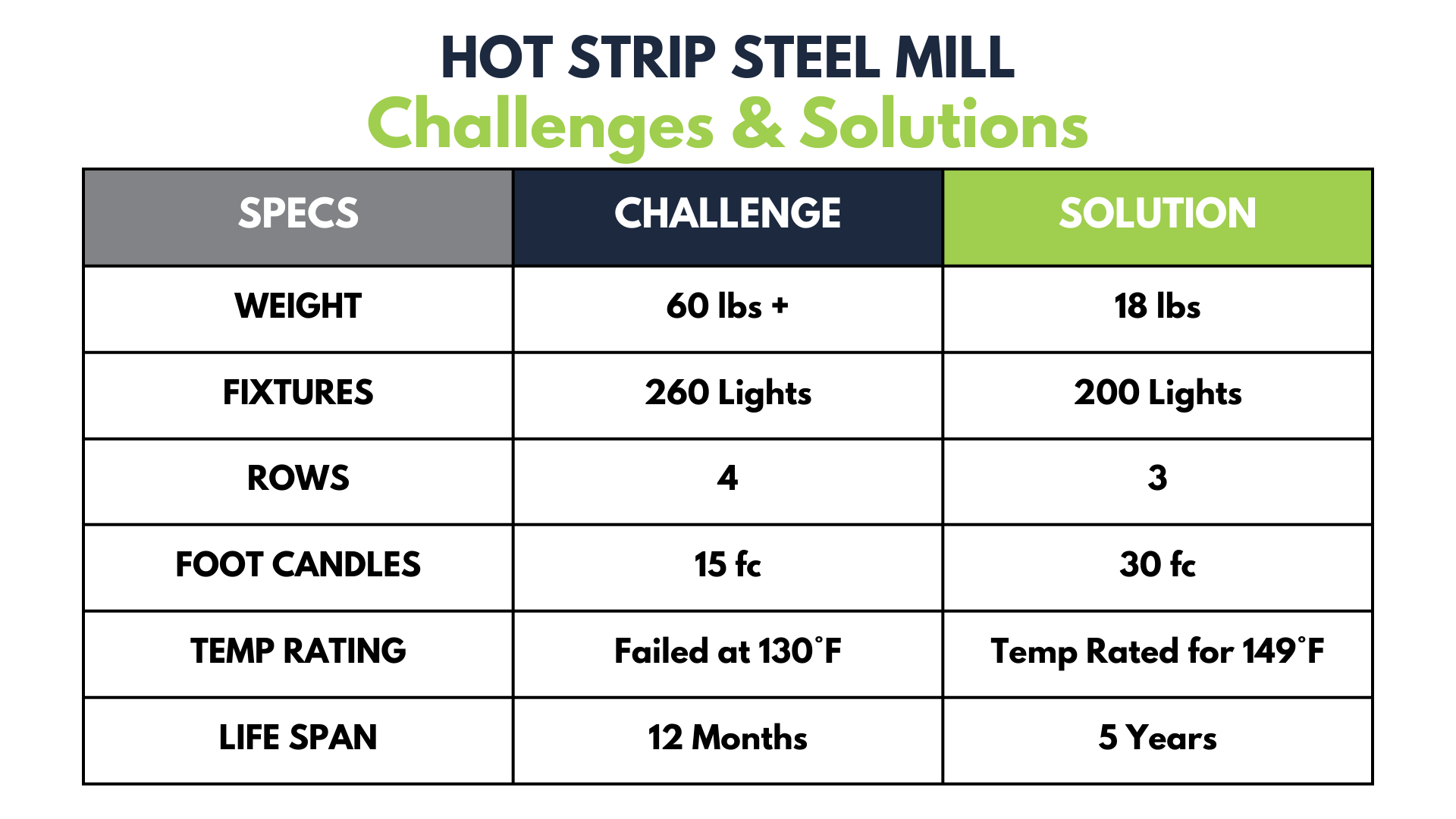

Fixture Weight

The current HPS fixture causing the mill problems weighs over 60 pounds. We replaced this fixture with our high bay fixture that weighs only 18 lbs. At almost four times lighter, our fixture makes it easier for workers to install and maintain the lighting.

Removed One Row of Lighting (25% Less Fixtures)

Before the mill switched to our LED lighting, they had four rows of lighting for a total of 260 fixtures. Since our LED lighting was so much brighter, we were able to eliminate an entire row of lighting, decreasing the amount of fixtures required by 25%. This drastically reduced the costs of lighting and labour for the installation as the customer only needed to purchase 200 fixtures to replace their current 260 fixtures.

Doubled Lighting Levels

We were able to double the lighting output even while reducing the number of fixtures needed. During our follow-up audit we saw an increase in the amount of foot-candles recorded. The steel mill had an average of 15 foot-candles with their old fixtures but after replacing the HPS fixtures with LED lighting, they received an average of 30 foot-candles. That’s twice as bright with 25% less fixtures!

Life Span & High-Temperature Solution

The main issue the customer was facing was due to the high temperatures in the steel mill. The 130-degree Fahrenheit temperatures were causing the lights to fail and require replacing within 12 months. The customer did try a different LED brand but had the same issues due to the high temperatures.

Our LED replacement fixture has a temperature rating of 149 degrees Fahrenheit (65 degrees Celsius). Over the last 15 years, we have sold thousands of these fixtures into hot mills and have had these lights last for up to 10 years without any issues. We stand behind the top-quality components in our fixtures and offer a guaranteed lifespan of 5 years in these extreme temperature environments.

Easy Replaceable Driver

The previous LED lighting that this hot mill tried, had a driver that was built-in to the fixture. Meaning it was not replaceable. When the high temperatures caused issues, they had to replace the entire fixture instead of just replacing the failed driver. In the LED replacement lighting that we provided, the driver sits on top of the fixture and is easy to replace down the road if any issue with the driver arises.

Quick Lead Time

Finally, the customer had a planned maintenance shutdown scheduled so they were in a rush for new fixtures but had a tight deadline. We received the order for 200 fixtures and because we had these fixtures in stock in our warehouse, we were able to ship all 200 lights out quickly and beat the shutdown deadline. The customer received all 200 fixtures only 18 days after issuing us the purchase order.

Interested in Your Own Free On-Site Lighting Audit?

We offer free on-site audits for heavy industrial plants. Our heavy industrial lighting specialists will come to your plant and complete light readings and temperature measurements to provide you with LED lighting fixture recommendations.

We want to learn about your environment and understand what your lighting challenges are because once we truly understand the problem, we can work with you to provide a solution.

Visit us at ledinaction.com/audit to learn more about our free onsite industrial audit.