problem

Steel, paper, glass factories, and other manufacturing hot mills often experience drastic temperature fluctuations and require an industrial lighting solution with extremely high operating temperatures. Finding a solution to this problem is difficult as drivers begin to fail in hot environments. Light fixtures don’t last long and hot mills are faced with the challenges of costly replacement lighting as well as safety concerns due to failing lights.

Some of the environments that high operating temperatures occur are in dryer hoods, cooling beds, furnace rooms, and ladle cranes.

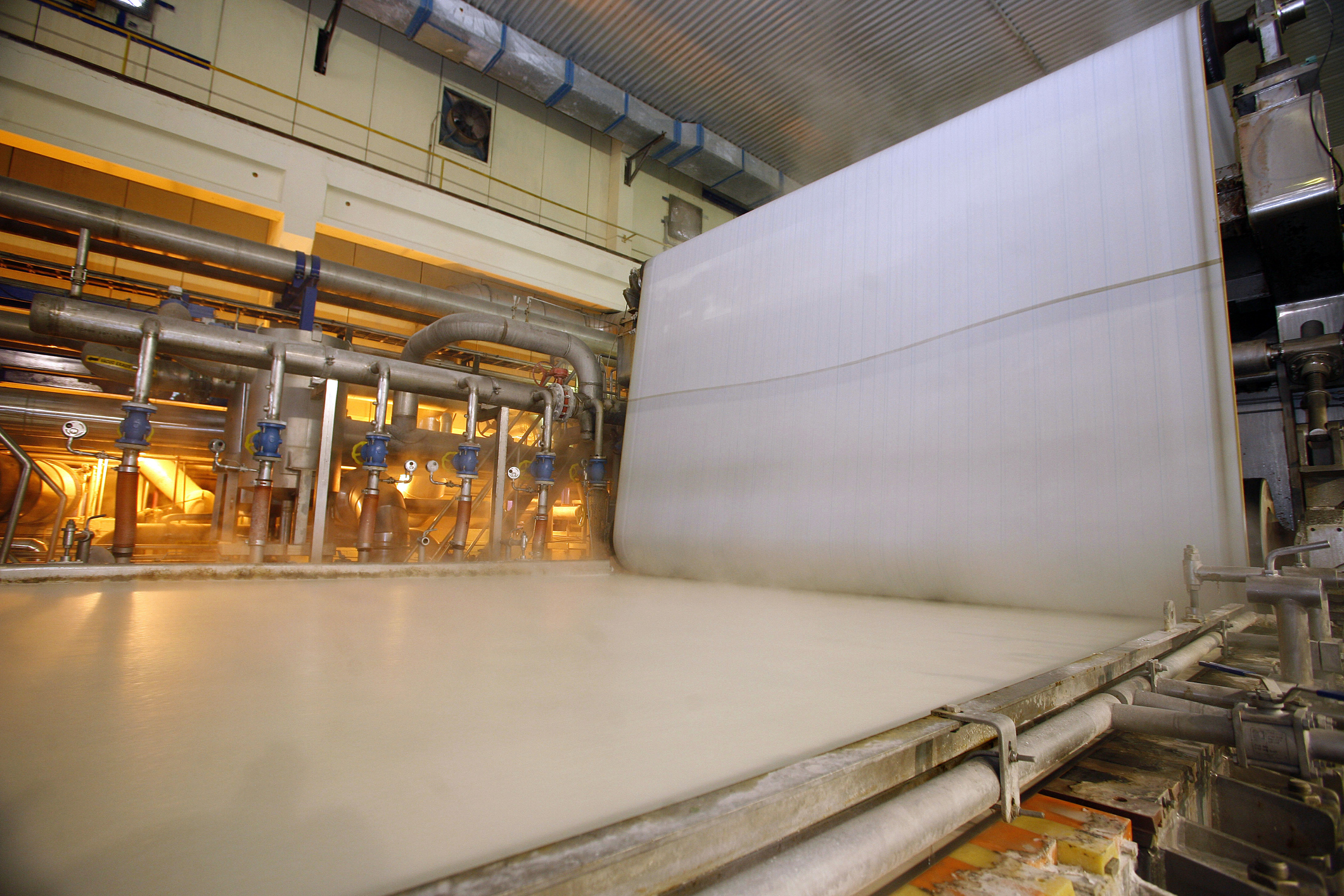

Dryer Hoods:

Dryer hoods can be found in paper plants where they use high temperatures to dry out the newly created wet paper. Once dry, the paper will eventually be rolled into large rolls for shipping. Temperatures in this area can reach up to +85-100°C.

Cooling Beds:

A cooling bed is an area where hot steel or glass air-cools in a steel or glass plant. The steel coils, slabs, and bars need to cool for several hours or days before they can be loaded for shipping. Temperatures in this area can reach up to +85-100°C.

Furnace Rooms:

The furnace in steel plants or glass plants is where they heat the ingredients to make steel or glass, usually inside of the ladle. This can be new steel/glass or recycled steel being melted down. Temperatures can reach up to +1500°C where the steel is being melted.

Ladle Cranes:

In steel plants or glass plants, a ladle crane is a crane that carries the ladle filled with newly made molten steel or glass over to where the molten can be poured into moulds. Temperatures in this area can reach up to +500°C for short periods.

Instead of replacing lights regularly, use our LED lighting fixtures that can withstand high temperatures. We have spent the last ten years finding a solution to this unique challenge and our lights have been proven to withstand extreme temperature environments.

solution

Our rugged LED fixtures are built to be able to withstand high temperatures and fluctuations and can bring you brighter than expected lighting in these harsh environments. We have come up with the following solutions for high-temperature applications.

Solution #1:

One of our solutions is a remote mount option that mounts the driver in a temperature-controlled box away from the hot environment.

Solution #2:

We also have light fixtures that have an operating temperature up to +100°C that does not have a driver. These driverless LED lights can withstand higher temperatures without the worry of a driver failing.

Solution #3:

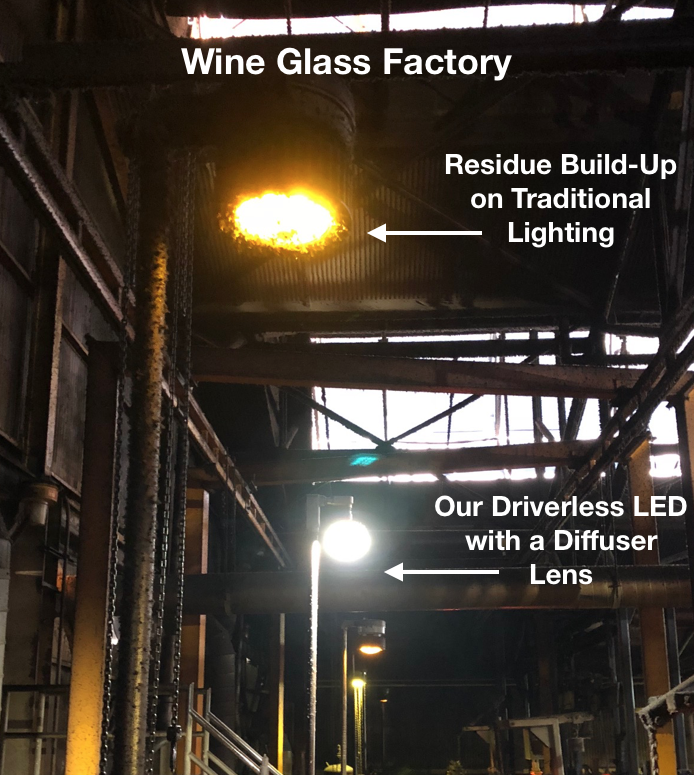

Our third solution is to add high-temperature modifications to our fixtures. We have a ROBAX glass lens upgrade that withstands temperatures up to +760°C. Our driverless LED also has the option to add a diffuser lens that protects the fixture lens from corrosion or residue as it can be replaced as required.

case studies

All of our case studies have had success with our high-temperature lighting solutions for longer than traditional lighting, most for several years now.

Case Study #1: NSF Grade Remote Mount

A paper plant was faced with the challenge of needing an NSF grade light fixture that could also withstand temperatures up to +100°C. These requirements were necessary as they produced paper packaging for the food industry supplying cupcake wrappers, cereal boxes, gum wrappers, and more. Our solution was to use our Food Processing Light fixture with a high-temp driver that was mounted 250 feet away from the high-temperature area in an air-conditioned box.

Case Study #2: Driverless LED with Diffuser Lens

A wine glass bottle manufacturer was faced with the challenge of residue building up on the lens of their current light fixtures causing a decrease in lighting levels and expensive replacement costs. This manufacturer also required a fixture that could withstand extreme heat temperatures. Our solution was providing the manufacturer with our driverless LED light that can withstand temperatures up to +100° with an added diffuser lens modification. The diffuser is a cost-efficient lens that can be replaced easily when residue builds up.

Case Study #3: ROBAX Glass Lens Modification

One of the challenges that faced a steel manufacturing plant was that they required a light that could withstand heavy vibration and voltage fluctuations but it also needed to withstand a high-temperature environment. Our solution for the steel plant was our CHB High Bay fixture with the added modification of the ROBAX glass lens. While the ROBAX lens does not change the temperature rating of the fixture, it drastically reduces the heat getting into the components of the fixture. This allows the fixture to be used in an environment that is susceptible to extreme temperature spikes in a steel manufacturing plant.

how to work with us

With industry-leading heat management technology, our robust fixtures are proven to withstand hot ambient environments. Thousands of our fixtures can be found in several of the world’s largest steel manufacturing plants, hot mills, paper mills, glass factories, and refineries. With over 10 years of success in high-temperature applications, LED in Action is quickly becoming the industry standard for high temp applications.

We sell to national distributors such as Guillevin, WESCO, Rexel, GEXPRO, Graybar, and more. We’ll work with your local distributor of choice throughout both the United States and Canada.

Contact us today to have a representative answer any questions or provide more information about your specific applications.