Over the years we have encountered all kinds of lighting on many kinds of cranes.

Here are the top 4 issues that our lights have solved:

1. Man Hours

Imagine the amount of time it takes to change one light bulb hundreds of feet in the air. Never mind the cost of equipment and arrange a time for all of this to take place. It is inevitable that as soon as you change a couple of light bulbs… two days later more are out. It’s an endless cycle.

2. Broken Bulbs Due to Vibration

Can you imagine, you finally have your nice fresh light bulbs up after coordinating the manpower, the equipment, and the time – just for them to be broken from vibration! This would have to be a maintenance department nightmare.

3. Safety

Why would we need to talk about safety? It’s only thousands of pounds swinging above people or equipment below. What if you were not able to see as clearly as you are operating this machine?

4. Lumen Decay Due to Moisture & Heat

After all of this, you make the decision to buy LED lights but you choose the cheapest one you could find. Well, now you aren’t dealing with the light bulbs, but you have half-lit or blinking lights. The savings you thought you would get never materialized.

Luckily we have 10 years of expertise and can help you find the perfect solution!

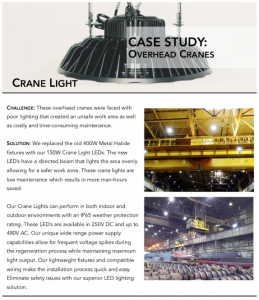

Our CHB lights are great crane lights. You can take a look at how they helped create a safe work environment and saved man-hours by looking at our Overhead Cranes Case Study.

Or do you need something a little more powerful? Well, we have you covered!

Our SuperLux light is lightweight at only 30lbs, comes with large lumen packages of 72,000 or 96,000 lumens, and is completely sealed to prevent moisture and dust from entering. It has a temperature rating of -30°C~+50°C with further testing pending on higher temperatures. The added safety measures of the SuperLux are the 3G vibration-rated brackets, surge suppressors, high-temperature modifications, and safety cables.